The only difference between the perforator bench is that the perforator bench is mainly used for drilling smaller diameters, including self-drilling pipes, where the laser beam control system can achieve the highest accuracy when drilling a sleeve or an immediately installed pipe.

However, the larger auger machine does not have a control system and larger diameters are drilled. The ideal condition for auger drilling is soft soil, where the drilled lengths reach up to 120 meters (depending on the soil) and it is also possible to install and renovate self-flowing pipelines.

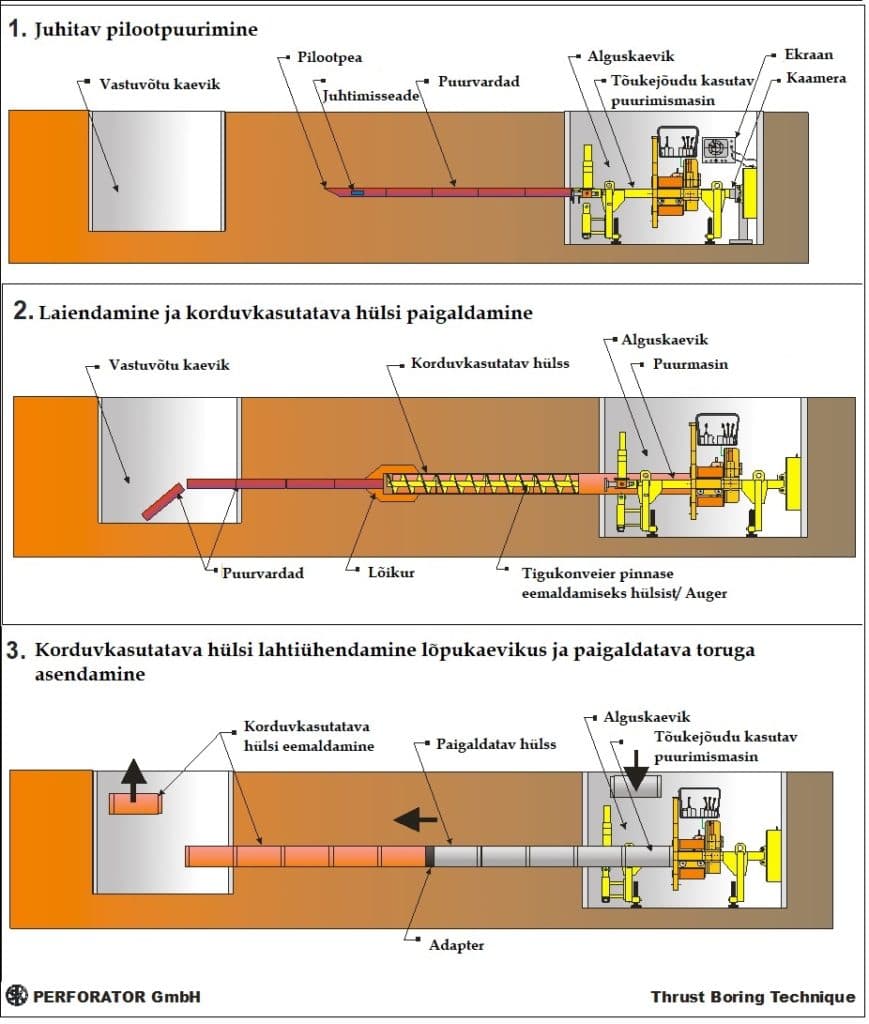

• The prepared sleeve is connected to the pusher

• After drilling the first sleeve, the machine is pulled back on the frame and a new pipe is added and the augers are connected to each other.

• Excavator and / or for digging and lifting

• A support frame and machine are installed in the initial trench at the height and slope specified by the customer

• The auger is placed in the sleeve

• The prepared sleeve is connected to the pusher

• After drilling the first sleeve, the machine is pulled back on the frame and a new pipe is added and the augers are connected to each other.

• After drilling is completed, all augers are pulled out of the pipe into the starting trench and opened one by one.

• The drill head is disconnected

• The remaining machines are proven out of the hole

• The sleeve is cleaned

• The work is completed and the desired piping can be installed in the sleeve.

Technologically speaking, the pipe is pressed into the ground using a frame in the trench during auger drilling. The cage in front of it must correspond to the diameter of the pipe to be installed in the sleeve (so that the stones do not get between the cage and the pipe to be drilled and clog the screw conveyor and so that there is no subsidence). Also so that the auger inside the pipe removes soil residues from the drilling.

Before starting to drill, the drilling direction and inclination are set, as the machine can no longer be oriented during drilling as can be done with directional drilling. After installing the pipe, the drill head is removed and the screw conveyor in the pipe is retracted, the pipe is cleaned of soil and the desired piping is installed in the sleeve.